Our products are not an end in themselves.

Comprehensive containment begins before the process, includes all

environmental factors and, above all, is consistent in itself.

Let us advise you.

As a filter system manufacturer, our

competencies cover a wide range of complex fields of knowledge.

In addition to manufacturing know-how and process engineering basics, we have knowledge of filtration, ergonomics, explosion protection, control technology, fluid mechanics, containment and much more.

We supply you with the right equipment at the right time!

We are at your side with help and advice: we not only help with

planning and procurement, but

also with the commissioning and disposal of our filter systems.

Supply air filter systems

Our supply air filter systems are perfectly adapted to your needs. Complete monitoring of the filter stages, frequency control of the fan and potential-free signal exchange are part of the basic package.

Laboratory dedusting systems

Complete monitoring of all filter stages, frequency control for the fan and signal exchange via potential-free contacts round off the basic package as a simple, cost-effective solution;

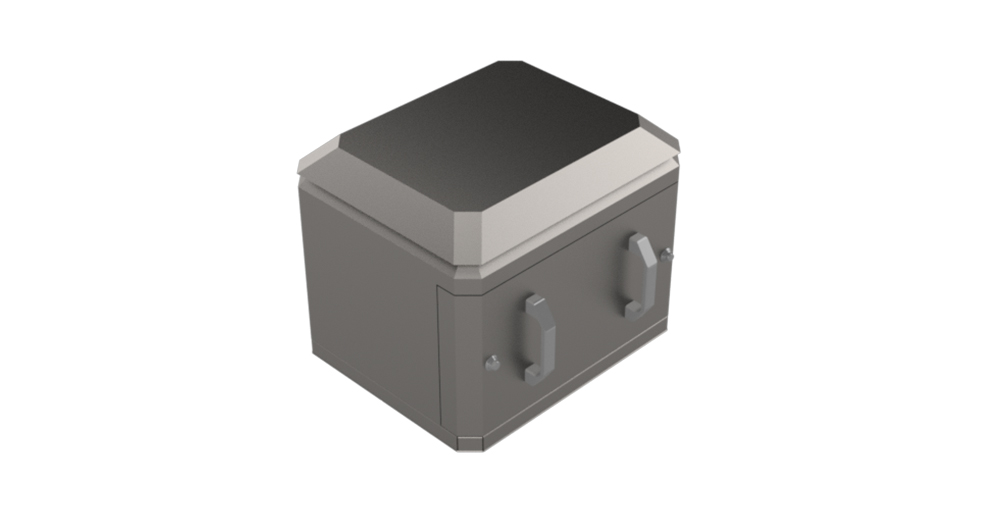

Compact dust extractors

Primary and secondary explosion protection are standard in all our systems; We avoid dust-explosive atmospheres and ignition sources; Contact us for a comprehensive consultation.

Our products

Our Products are not an end in themselves.

They are designed to solve your problems;

Comprehensive containment begins before the process, takes all environmental factors into account and, above all, is coherent. Let us advise you.

Engineering

Service

Training

- MORE ABOUT OUR PRODUCTS EXPERIENCE

About us

Do not be one of many

Our young and dynamic team focuses on your application and works with you to create your ideal dust extraction solution quickly and flexibly; Your advantage here is obvious: you want a dust extractor that provides you with the signals you want in your Want to display HMI? You want a dust extractor that fits perfectly with your systems? And of course you want a dust extractor that meets your requirements and is neither oversized nor undersized? All this and much more is possible in a joint development project. We are also happy to offer you several types of system to suit your portfolio.

You know your Application and we are our

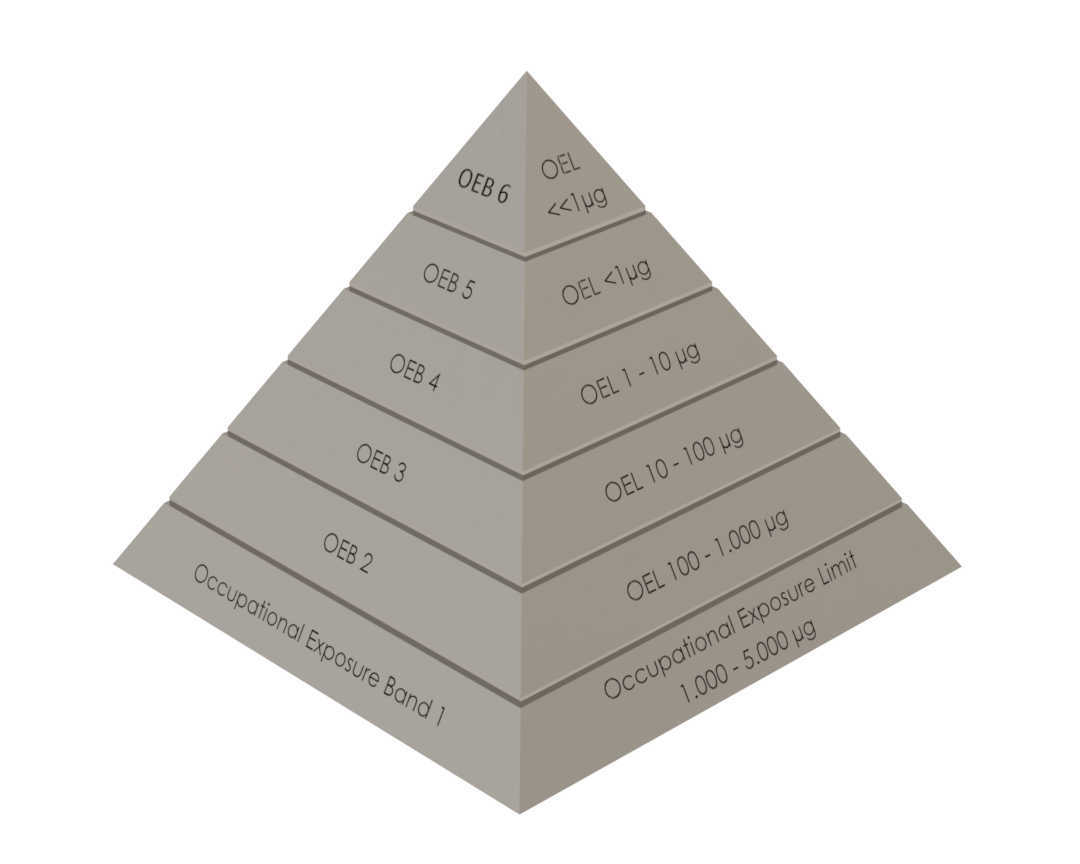

You can rely on our expertise to ensure that all aspects such as ergonomics, GMP-compliant design and, above all, safety (user protection and product protection go hand in hand with us) are fully taken into account; Here we focus on the topics of clean air values, containment and explosion protection; Our aim is to give you a good feeling through security and at the same time to make the integration and handling of the system as easy as possible. We not only take into account German standards, but also international standards such as the American explosion protection regulation NFPA 69 on.

Competencies

As Filteranlagenhersteller our Competencies over a variety of complex Fields of knowledge.

In addition to manufacturing know-how and process engineering fundamentals, we have knowledge of filtration, ergonomics, explosion protection, control technology, fluid mechanics, containment and much more; For this reason, we have compiled some basics from the most important topics on our site; Of course, we can only provide an overview of these topics online; However, we are happy to advise you in detail and offer training on these topics;

Find out more about containment, dedusting, explosion protection and documentation.

- MORE ABOUT OUR COMPETENCE EXPERIENCE

Contact information

- +49 (0) 6404 90798 20

- +49 (0) 6404 90798 18

-

-

Vesch Technologies GmbH

Am Schwanensee 11

35423 Lich - info@vesch-technologies.com

Write to us

We are available for you at any time.